Hot Spot Monitoring and early Arc-Flash protection

-

Hot Spot Monitoring Protection

Hot Spot Monitoring is a non-conductive temperature monitoring and alarming system that identifies potential hot spots and enables user to predict the failures in electrical equipment.

Current flowing through electrical connections (lugs, screw terminals, circuit breaker, busbar joints, etc.) is the main cause for electrical hot spots.

Such Hot Spots would normal tend to show up under infrared camera scans but only for those areas where safe access is available to allow the camera to safely scan connections and only when a scan is scheduled.

The installation of a Hot Spot Monitoring Protection system gives 24hr monitoring and can cover those hard to access sections of any Electrical installation.

BMC are available to discuss your electrical monitoring and protection needs.

Risk Reduction Benefits

|

Description |

Open Door Thermography |

Hot Spot Monitor |

|

Incident energy exposure |

High |

None |

|

Special skills & certifications |

Required |

No |

|

Access to hidden points |

No |

Yes |

|

Alarm/Indication |

No |

Yes |

|

Plant-wide integration |

No |

Yes |

|

Inspection frequency |

Intermittent |

Continuous |

|

Data logging |

Manual |

Auto |

-

Arc-Flash Protection

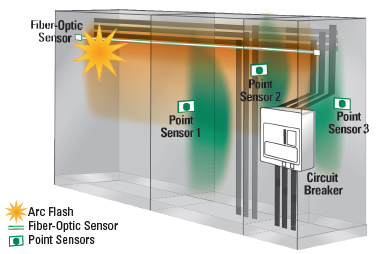

With Arc-Flash detection and protection coming to the forefront more and more these days within Electrical Switchgear.

BMC can offer practical solutions to our clients to meet this growing demand.

By installing an arc-flash relay that limits arc-fault damage by detecting the light from an arc flash and rapidly tripping the feeder breaker.

The unit is well suited for switchgear, transformer and power converter applications.

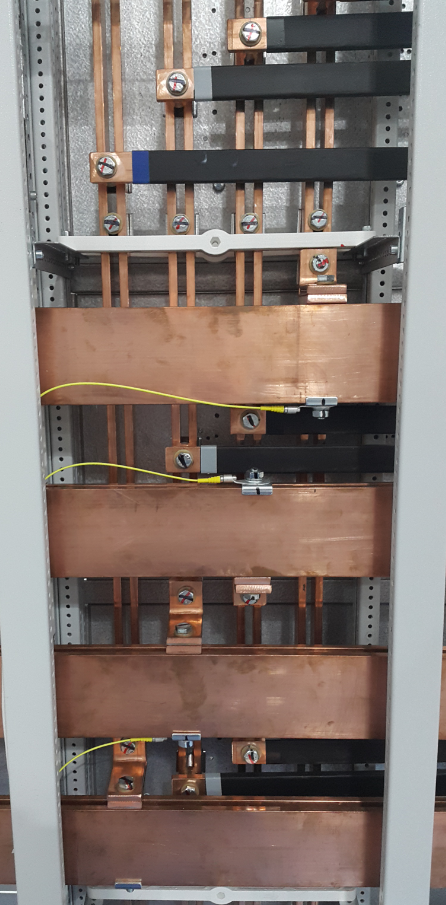

Arc-Flash Relays and sensors are easily installed in retrofit projects and new switchgear with little or no re-configuration.

In general it is recommended to mount 1 or 2 sensors per cubicle to cover all horizontal and vertical bus bars, breaker compartments, drawers, and anywhere that there is a risk for an arc fault.

Key Benefits

- Shunt tripping of Breaker faster than the Breaker protective unit.

- Limits arc-flash damage and risk of injury.

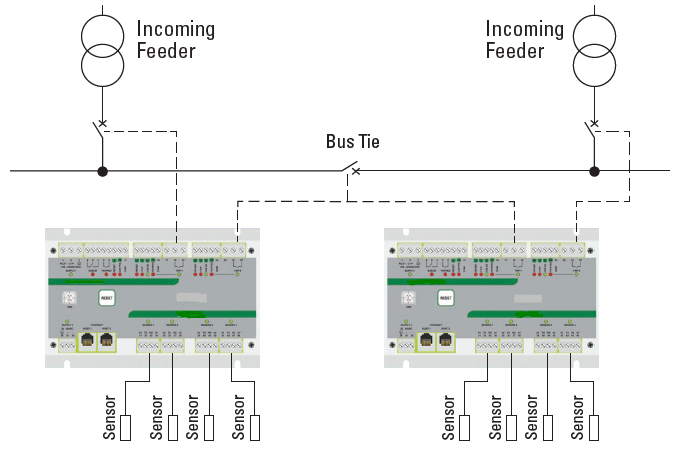

- Supports applications such as upstream breaker tripping or tie breaker tripping.

- Multiple AF0500 units can be interconnected to form a system.

- Zone Triping.

- Modbus® TCP communication.